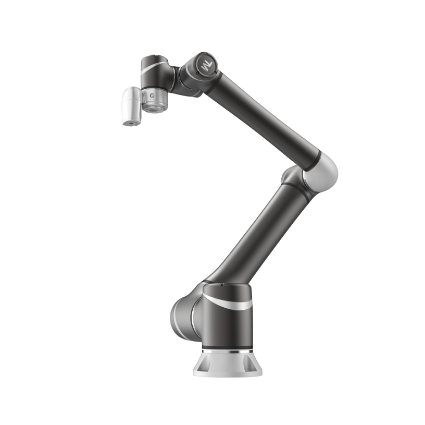

Magetsi Welding Huazhongcnc kana Hnc Hsr Diki 6 Axis Robot Cobot Arm

Magetsi Welding Huazhongcnc kana Hnc Hsr Diki 6 Axis Robot Cobot Arm

Main Category

Indasitiri robhoti ruoko / Kubatirana robhoti ruoko / Magetsi gripper / Intelligent actuator / otomatiki mhinduro

Application

Iyo TM12 ine kureba kwekusvika mumarobhoti edu akateedzana, ichigonesa kushanda kwekubatana, kunyangwe mumashandisirwo anoda maindasitiri-chikamu kunyatsoita uye kusimudza kugona. Iine huwandu hwezvinhu zvinobvumira kuti ishandiswe zvakachengeteka pedyo nevashandi vevanhu, uye pasina chikonzero chekuisa zvipingamupinyi zvakakura kana fenzi. TM12 isarudzo yakanakisa yecobot otomatiki yekuvandudza kuchinjika, uye kuwedzerakubereka.

Iine kirasi-inotungamira yekuona sisitimu, yepamusoro AI tekinoroji, yakazara kuchengetedzwa, uye nyore kushanda,AI Cobot ichatora bhizinesi rako mberi kupfuura nakare kose.Tora otomatiki kune inotevera nhanho nekuwedzera chibereko, kuvandudza mhando, uye kuderedza mitengo.

Features

SMART

Ramangwana-uchapupu Cobot Yako neAI

• Automated optical inspection (AOI)

• Kuvimbiswa kwehutano & kuwirirana

• Kuwedzera kubudirira kwekugadzira

• Kuderedza mari yekushandisa

SIMPLE

Hapana ruzivo runodiwa

• Graphical interface kuitira nyore hurongwa

• Process-oriented editing workflow

• Kutungamira kuri nyore kwemaoko kwezvinzvimbo zvekudzidzisa

• Kukurumidza kuona kururamisa ne calibration board

SAFE

Kuchengetedzwa kwekubatana ndicho chinhu chatinokoshesa

• Inopindirana neISO 10218-1:2011 & ISO/TS 15066:2016

• Kuonekwa kweCollison nekumira kwechimbichimbi

• Chengetedza mutengo uye nzvimbo yezvipingamupinyi & fenzi

• Isa miganho yekumhanya munzvimbo yekushandira pamwe

AI-powered cobots inoziva kuvapo uye kutaridzika kwenzvimbo yavo uye zvikamu kuita ongororo yekuona uye ane simba ekutora-nenzvimbo mabasa. Nesimba shandisa AI kumutsara wekugadzira uye uwedzere kugadzirwa, kuderedza mitengo, uye kupfupisa kutenderera nguva. Chiono cheAI chinogona zvakare kuverenga mhedzisiro kubva kumashini kana midziyo yekuyedza uye kuita sarudzo dzakafanira zvinoenderana.

Kunze kwekuvandudza otomatiki maitiro, AI-inotyairwa cobot inogona kuteedzera, kuongorora, uye kubatanidza data panguva yekugadzira kudzivirira kukanganisa uye kugadzirisa kunaka kwechigadzirwa. Nyatsovandudza fekitori yako otomatiki neseti yakazara yeAI tekinoroji.

Marobhoti edu anodyidzana akashongedzerwa neyakasanganiswa yekuona sisitimu, ichipa cobots kugona kuona zvakavatenderedza izvo zvinonyanya kuwedzera cobot kugona. Chiono cheRobhoti kana kugona "kuona" uye kududzira data yekuona mumirairo yekuraira ndechimwe chezvinhu zvinoita kuti tive vakuru. Iyo inoshandura-mutambo wekuita nemazvo mabasa munzvimbo dzekushanda dzinochinja, kuita kuti mashandiro afambe akapfava, uye otomatiki maitiro zvinobudirira.

Yakagadzirwa nevashandisi venguva yekutanga mupfungwa, ruzivo rwekugadzira hachisi chinhu chinodiwa kuti utange neAI Cobot. An intuitive click-and-drag motion uchishandisa yedu flow programming software inoderedza kuoma. Tekinoroji yedu ine patented inobvumira vashandisi vasina ruzivo rwekodha kuronga chirongwa chipfupi semaminitsi mashanu.

Inherent kuchengetedza ma sensors anomisa AI Cobot kana kubatwa kwepanyama kwaonekwa, kuderedza kukuvadzwa kunogona kuitika kwenzvimbo isina kudzvanywa uye yakachengeteka. Iwe unogona zvakare kuseta yekumhanyisa miganho yerobhoti saka inogona kushandiswa munzvimbo dzakasiyana siyana padivi pevashandi vako.

Related Products

Kuunza yedu yepamusoro-soro 6-axis dhigirii yerusununguko indasitiri welding robhoti ruoko, mhinduro yakakwana kune yako maindasitiri welding zvinodiwa. Maoko edu emarobhoti akagadzirwa kuti ape yakanyanya kurongeka, kunyatsoita uye kugadzirwa kwekutora uye welding mabasa munzvimbo dzeindasitiri. Semutengesi anotungamira wekutengesa, takazvipira kupa zvigadzirwa zvemhando yepamusoro pamitengo yemakwikwi kumabhizinesi ari kutsvaga kugadzirisa mashandiro uye kuwedzera kugadzirwa.

Yedu 6-axis madhigirii erusununguko indasitiri welding robhoti ruoko inopa huwandu hwakasiyana hwekufamba uye kuchinjika, ichiibvumira kubata yakaoma welding mabasa zviri nyore. Iine tekinoroji yayo yepamusoro, inogona kuita nemazvo mashandiro ewelding munzira dzakasiyana siyana, zvichiita kuti ive yakanaka kune akasiyana siyana maindasitiri ekushandisa. Ruoko rwerobhoti rwakashongedzerwa nekucheka-kumucheto sensors uye zvinodzora kuti ive nechokwadi chechokwadi uye chinopindirana welding mhinduro nguva dzese.

Chimwe chezvinhu zvakakosha zvemaoko edu erobhoti ndeye mushandisi-ane hushamwari interface, iyo inobvumira nyore kuronga uye kushanda. Izvi zvinoreva kuti kunyange vashandi vane kudzidziswa kushoma vanogona kukurumidza kudzidza kushandisa robhoti ruoko zvinobudirira, kuchengetedza bhizinesi rako nguva uye mutengo webasa. Pamusoro pezvo, iro robhoti ruoko rwakagadzirirwa kuve yakasimba uye yakaderera kugadzirisa, ichipa yakavimbika uye inodhura-mhinduro yekushanda kwemaindasitiri welding.

Semutengesi wekutengesa, tinonzwisisa kukosha kwekupa mitengo yemakwikwi pasina kukanganisa pamhando. Yedu 6-axis DOF industrial welding robhoti ruoko ine mutengo wemakwikwi uye inodhura mari yekudyara kumabhizinesi ari kutsvaga kukwidziridza kugona kwavo welding. Kunyangwe iwe uine chitoro chidiki kana hombe maindasitiri nzvimbo, maoko edu emarobhoti akakwana mukuvandudza yako welding maitiro uye kuwedzera chibereko.

Muchidimbu, yedu 6-axis madhigirii erusununguko indasitiri welding robhoti ruoko ndiyo yekupedzisira mhinduro kune mabhizinesi ari kutsvaga akavimbika, anoshanda uye anodhura-inoshanda welding mhinduro. Iine tekinoroji yayo yepamusoro, mushandisi-inoshamwaridzana interface uye mutengo wemakwikwi, yakanakira kutora uye welding mabasa munzvimbo dzeindasitiri. Bata nesu nhasi kuti udzidze zvakawanda nezve marobhoti maoko edu anogona kubatsira bhizinesi rako.

Specification Parameter

| Model | TM12M | |

| Kurema | 32.8KG | |

| Maximum Payload | 12KG | |

| Svika | 1300mm | |

| Joint Ranges | J1,J6 | ±270° |

| J2,J4,J5 | ±180° | |

| J3 | ±166° | |

| Speed | J1,J2 | 120°/s |

| J3 | 180°/s | |

| J4 | 180°/s | |

| J5 | 180°/s | |

| J6 | 180°/s | |

| Typical Speed | 1.3m/s | |

| Max. Speed | 4m/s | |

| Kudzokorora | ± 0.1mm | |

| Degree yerusununguko | 6 kutenderera majoini | |

| I/O | Kudzora bhokisi | Digital kupinda:16 Digital kubuda:16 Analogi yekupinda:2 Analogi yakabuda:1 |

| Tool Conn. | Digital kupinda:4 Digital kubuda:4 Analogi yekupinda:1 Analog kubuda: 0 | |

| I/O Power Supply | 24V 2.0A yekudzora bhokisi uye 24V 1.5A yechishandiso | |

| IP Classification | IP54(Robot Arm); IP32(Kudzora Bhokisi) | |

| Kushandisa Simba | Yakajairika 300 watts | |

| Tembiricha | Robhoti rinogona kushanda mutembiricha ye0-50 ℃ | |

| Utsanana | ISO Kirasi 3 | |

| Magetsi | 22-60 VDC | |

| I/O Interface | 3xCOM, 1xHDMI, 3xLAN, 4xUSB2.0, 2xUSB3.0 | |

| Kukurukurirana | RS232, Ethemet, Modbus TCP/RTU (tenzi & muranda), PROFINET (Sarudzo), EtherNet/IP(Sarudzo) | |

| Programming Environment | TMflow, flowchart yakavakirwa | |

| Certification | CE, SEMI S2 (Sarudzo) | |

| AI & Vision*(1) | ||

| AI Basa | Classification, Chinhu Kuonekwa, Segmentation, Anomaly Detection, AI OCR | |

| Application | Positioning, 1D/2D Barcode Kuverenga, OCR, Defect Detection, kuyerwa, Assembly Check | |

| Positioning Kururama | 2D Nzvimbo: 0.1mm*(2) | |

| Ziso Muruoko (Yakavakirwa mukati) | Auto-yakatarisa ruvara carmera ine 5M resolution, Kushanda kureba 100mm ~ ∞ | |

| Ziso neruoko (Zvichida) | Tsigira Maximum 2xGigE 2D makamera kana 1xGigE 2D Kamera +1x3D Kamera*(3) | |

| *(1)Hapana akavakirwa-mukuona marobhoti maoko TM12X, TM14X, TM16X, TM20X aripo zvakare. *(2)Iyo data iri patafura iyi inoyerwa neTM murabhoritari uye chinhambwe chekushanda i100mm. Zvinofanira kucherechedzwa kuti mumashandisirwo anoshanda, kukosha kwakakodzera kungave kwakasiyana nekuda kwezvinhu zvakaita sepa-saiti ambient light source, hunhu hwechinhu, uye nzira dzekuona zvirongwa zvinozokanganisa shanduko mukurongeka. *(3)Tarisa kune webhusaiti yepamutemo yeTM Plug & Tamba yemhando dzekamera dzinoenderana neTM Robot. | ||

Bhizinesi redu